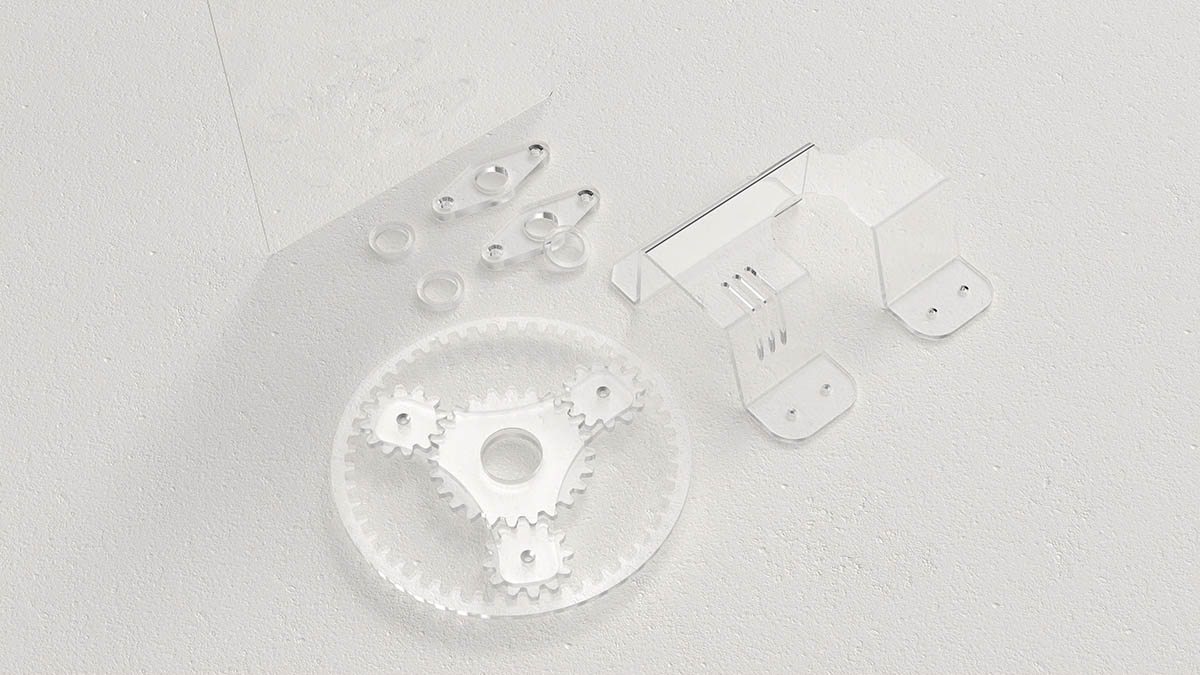

PMMA XT (Extruded Acrylic)

Plastic

PMMA XT, or extruded acrylic, is a transparent plastic with high clarity and excellent UV resistance. The material is lightweight, easy to process, and a popular alternative to glass. Thanks to the extrusion process, PMMA XT offers higher dimensional stability and is more cost-effective than cast PMMA, making it ideal for flat applications with standard tolerances.

Well-known trade names for PMMA XT include Altuglas®, Plexiglas® XT, Acryplast®, and Perspex® XT. These grades are widely used in advertising, interior design, construction, and mechanical engineering.

- Laser cutting

- Milling